torque wrench instruction manual

Need a torque wrench manual? Find easy-to-understand guides & instructions for all your wrenching needs at Moupma. Don't guess, get precise!

Torque wrenches are vital for precise fastener tightening, essential for both professional mechanics and DIY projects, ensuring correct application and preventing damage.

These instruments guarantee bolts are neither too loose nor over-tightened, maintaining structural integrity and safety across various applications.

Regular calibration, as offered by services like GMS Instruments with GEDORE tools, is crucial for maintaining accuracy and reliable performance.

What is a Torque Wrench?

A torque wrench is a specialized tool designed to apply a precise amount of rotational force – torque – to a fastener like a nut or bolt. Unlike standard wrenches that simply tighten, a torque wrench allows the user to control how much tightening force is applied, preventing over-tightening or under-tightening.

This control is critical because fasteners have specific torque specifications determined by the manufacturer. Applying the correct torque ensures a secure connection without damaging the fastener or the joined materials. It’s an essential tool for automotive work, machinery maintenance, and any application where fastener integrity is paramount.

Essentially, it’s a measuring tool as much as a tightening tool, providing a quantifiable measure of the applied force. Proper use, guided by a torque wrench instruction manual, is key to achieving reliable and safe results.

Why Use a Torque Wrench?

Using a torque wrench is paramount for ensuring fastener integrity and overall safety. Incorrectly tightened fasteners can lead to component failure, potentially causing significant damage or even hazardous situations, especially concerning vehicle safety like wheel lug nuts.

Over-tightening can stretch or break bolts, while under-tightening can cause them to loosen over time. A torque wrench eliminates guesswork, guaranteeing fasteners are tightened to the manufacturer’s precise specifications. This is particularly crucial for critical engine components like connecting rod and main bearing bolts.

Investing in a torque wrench, and understanding its instruction manual, is a proactive step towards quality workmanship and long-term reliability, preventing costly repairs and ensuring peace of mind.

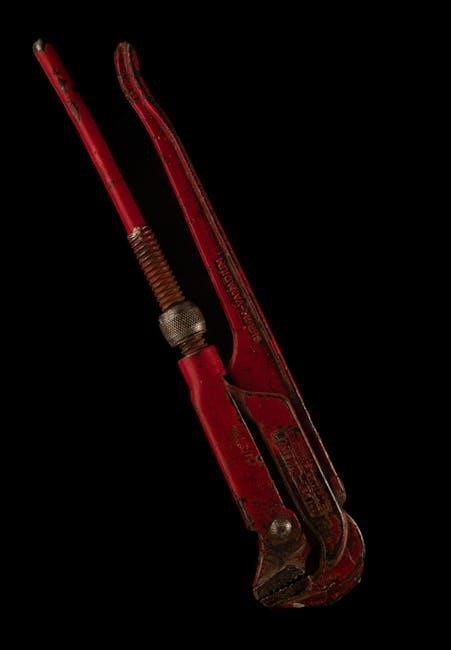

Types of Torque Wrenches

Torque wrenches come in various designs – click, beam, digital, and slip-type – each offering unique features for different applications and user preferences.

Click-Type Torque Wrenches

Click-type torque wrenches are among the most popular choices due to their simplicity and clear indication of reaching the desired torque. These wrenches are pre-set to a specific torque value, and when that value is achieved, the wrench produces an audible ‘click’ and a slight release of tension.

This tactile and auditory feedback alerts the user to stop applying force, preventing over-tightening. They are commonly used in automotive repair, assembly lines, and any application requiring consistent and accurate torque application. Proper use involves setting the torque, applying smooth pressure, and stopping immediately upon hearing and feeling the click. Regular calibration, like that offered for GEDORE wrenches, is vital to ensure continued accuracy and prevent inaccurate readings over time.

Beam-Type Torque Wrenches

Beam-type torque wrenches represent a more traditional and generally more affordable option. They feature a long beam with a pointer that indicates the applied torque on a calibrated scale. Unlike click-type wrenches, they don’t offer an audible or tactile signal when the target torque is reached; instead, the user must visually monitor the pointer.

This requires careful attention and a steady hand to avoid over-tightening. They are often favored for their simplicity and durability, needing less frequent calibration compared to other types. Accurate readings depend on a clear view of the scale during application. While less sophisticated, beam-type wrenches remain a reliable choice for many applications, especially where precise, repeatable torque isn’t paramount.

Digital Torque Wrenches

Digital torque wrenches offer the highest level of precision and user-friendliness. They utilize electronic sensors to measure torque and display it on a digital screen, often with audible and visual alerts when the target value is achieved. Many models allow users to set multiple torque settings and switch between units (Nm, ft-lbs, in-lbs) easily.

Advanced features like data logging and connectivity are common, enabling detailed torque records. Services like HBM offer recalibration for these advanced wrenches, ensuring continued accuracy. While generally more expensive, digital wrenches minimize the risk of errors and are ideal for critical applications demanding precise torque control and documentation.

Slip-Type Torque Wrenches

Slip-type torque wrenches, also known as break-over wrenches, are a simpler and more affordable option. They operate by bending slightly when the preset torque is reached, providing a tactile ‘slip’ sensation to the user. This indicates that the fastener is sufficiently tightened, preventing over-tightening.

These wrenches lack the precise readings of digital or click-type models, relying on the user’s feel and the wrench’s mechanical action. Regular calibration is still important, though less frequent than with more sophisticated types. They are suitable for applications where extreme accuracy isn’t paramount, but controlled tightening is still necessary for reliable assembly and safety.

Understanding Torque Units

Torque is measured in Newton-Metres (Nm), Foot-Pounds (ft-lbs), and Inch-Pounds (in-lbs); selecting the correct unit is vital for accurate fastener tightening.

Newton-Metres (Nm)

Newton-Metres (Nm) represent the metric unit of torque, signifying the force required to rotate an object a specific distance. It’s calculated by multiplying the force applied (in Newtons) by the length of the lever arm (in metres). This unit is widely adopted in automotive and industrial applications globally, offering a standardized measurement for precise tightening.

When using a torque wrench displaying Nm, ensure the fastener specification aligns with this unit. Incorrect conversion can lead to under- or over-tightening, compromising safety and component integrity. Many European vehicle manufacturers predominantly specify torque values in Nm, making familiarity with this unit essential for mechanics working on these vehicles.

Understanding Nm allows for consistent and repeatable results, crucial in precision assembly and maintenance. Accurate torque application, measured in Nm, prevents thread damage and ensures optimal clamping force.

Foot-Pounds (ft-lbs)

Foot-Pounds (ft-lbs) is a commonly used imperial unit for measuring torque, particularly prevalent in the United States automotive industry. It represents the amount of force needed to rotate an object using a one-foot lever arm. This unit directly correlates to the twisting force applied to a fastener, like a nut or bolt.

When referencing a torque wrench displaying ft-lbs, always verify the fastener’s torque specification is also in this unit. Improper conversion from other units, such as Newton-Metres, can result in significant errors. Many older vehicles and American manufacturers still utilize ft-lbs for torque specifications.

Consistent application of torque, measured in ft-lbs, is vital for ensuring proper clamping force and preventing component failure. Accurate readings contribute to vehicle safety and longevity.

Inch-Pounds (in-lbs)

Inch-Pounds (in-lbs) represent a smaller unit of torque measurement, frequently employed for fasteners requiring lower tightening forces. It signifies the force needed to rotate an object using a one-inch lever arm. This unit is particularly useful when working with sensitive components or smaller fasteners where precision is paramount.

Torque specifications in in-lbs are common in applications like electronics assembly, instrumentation, and certain automotive components. When using a torque wrench calibrated in in-lbs, ensure the specification matches the unit to avoid errors. Converting from ft-lbs requires careful calculation.

Employing the correct torque, measured in in-lbs, prevents damage to delicate parts and ensures reliable performance. Accurate tightening is crucial for maintaining the integrity of assembled systems.

Using a Torque Wrench: Step-by-Step

Proper torque application involves setting the correct value, using a firm grip, and applying force smoothly—ensuring fasteners are tightened to specification.

Setting the Torque Value

Precisely setting the torque value is the foundational step for effective wrench use. Begin by consulting the manufacturer’s specifications for the fastener you’re tightening; these values are critical for safety and performance.

On click-type wrenches, unlock the handle and rotate the adjustment collar until the desired torque is indicated on the scale. Ensure you’re using the correct units – Newton-Metres (Nm), Foot-Pounds (ft-lbs), or Inch-Pounds (in-lbs).

Digital torque wrenches allow for precise numerical input. Double-check the setting before each use, and remember to re-lock the handle to prevent accidental adjustments during application. Accurate setup guarantees the fastener receives the intended tightening force, preventing both loosening and damage.

Proper Grip and Technique

Maintaining a firm, controlled grip is paramount when using a torque wrench. Position your hand comfortably on the handle, ensuring a secure hold without excessive force. Avoid jerky movements; apply pressure smoothly and steadily throughout the tightening process.

Keep your body aligned with the wrench to maximize control and minimize strain. Pull the wrench in a slow, deliberate arc, using your entire arm rather than just your wrist.

For optimal accuracy, position yourself so you can view the scale or digital display clearly. Remember, consistent technique is key to achieving reliable torque readings and preventing errors that could compromise fastener integrity and overall safety.

Applying Torque Correctly

Begin by ensuring the torque wrench is set to the specified value for the fastener. Position the wrench squarely onto the nut or bolt head, avoiding any angled pressure. Initiate a slow, consistent pull, observing the wrench’s indicator – whether it’s a click, a needle, or a digital display.

Continue applying force until the wrench signals that the target torque has been reached. Do not continue pulling after the signal, as this can lead to over-tightening and potential damage.

Release the pressure smoothly and verify the setting before repeating the process on other fasteners. Correct application is vital for vehicle safety, especially with critical components like wheel lug nuts and engine fasteners.

Torque Wrench Calibration & Maintenance

Regular calibration is essential for accuracy; services like HBM offer on-site recalibration, minimizing downtime and ensuring reliable torque readings for critical applications.

Importance of Calibration

Calibration of a torque wrench isn’t merely a suggestion; it’s a necessity for maintaining accuracy and ensuring the reliability of fastened joints. Over time, and with consistent use, torque wrenches can drift out of specification due to wear and tear on internal components. This drift can lead to under-tightened or, more dangerously, over-tightened fasteners.

Under-tightening compromises the integrity of the assembly, potentially leading to loosening and failure. Conversely, over-tightening can stretch or break bolts, strip threads, and damage the components being fastened. Accurate torque application is particularly critical in applications like engine assembly and wheel lug nut tightening, directly impacting safety and performance.

Services like those offered by GMS Instruments, utilizing GEDORE calibration equipment, verify the wrench’s output against traceable standards, guaranteeing its precision. Regular calibration provides confidence in the tool’s readings and prevents costly errors or potential hazards.

Calibration Frequency

Determining the appropriate calibration frequency for a torque wrench depends heavily on usage. For professional workshops and high-volume applications, annual calibration is generally recommended, aligning with IRTE Workshop Accreditation guidance. Tools used daily or in critical safety applications – such as automotive repair or aerospace – require more frequent checks, potentially every six months.

Even less frequently used wrenches should be calibrated at least once a year to account for environmental factors and component degradation. If a wrench experiences heavy use, accidental drops, or is suspected of providing inaccurate readings, immediate calibration is essential.

HBM offers on-site recalibration services for their transfer torque wrenches, minimizing downtime. Consistent calibration ensures continued accuracy and adherence to quality control standards, safeguarding both the integrity of work and operator safety.

GEDORE Torque Wrench Calibration

GEDORE torque wrenches are renowned for their precision, but even the highest quality tools require periodic calibration to maintain accuracy. GMS Instruments provides specialized calibration and certification services specifically for GEDORE torque wrenches, ensuring they meet stringent industry standards.

Calibration involves a thorough inspection and adjustment process, verifying the wrench’s accuracy across its entire torque range. This process utilizes calibrated testing equipment to compare the wrench’s output against traceable standards. A detailed calibration certificate is provided, documenting the ‘as found’ and ‘as left’ readings.

Regular GEDORE wrench calibration, ideally annually for professional use, guarantees reliable performance and prevents potential errors that could compromise safety or product quality. Proper calibration extends the lifespan of the tool and maintains its value.

HBM Transfer Torque Wrench Recalibration

HBM offers convenient on-site recalibration services for its advanced TTS transfer torque wrenches, minimizing downtime and streamlining maintenance procedures for customers. Traditionally, calibration required sending tools to a lab, causing delays; HBM’s mobile service eliminates this inconvenience.

This service utilizes highly accurate transfer standards, traceable to national and international standards, to verify and adjust the wrench’s torque readings. Skilled technicians perform the recalibration process efficiently, ensuring minimal disruption to operations. A comprehensive report details the calibration results.

Regular recalibration of HBM transfer torque wrenches is crucial for maintaining precision in critical applications, guaranteeing reliable torque application and preventing costly errors. This proactive approach ensures optimal performance and extends the tool’s lifespan.

Critical Fasteners & Torque Specifications

Engine and wheel fasteners demand precise torque; connecting rod bolts and lug nuts are paramount for safety and performance, requiring strict adherence to specifications.

Engine Fasteners: Connecting Rod & Main Bearing Bolts

Engine fasteners, particularly connecting rod and main bearing bolts, are undeniably critical components demanding absolute precision during installation. Unlike less vital bolts, these directly influence engine stability and longevity. Incorrect torque can lead to catastrophic failure, ranging from reduced performance to complete engine seizure.

Manufacturers provide specific torque values – often expressed in foot-pounds or Newton-meters – that must be followed using a calibrated torque wrench. Under-torquing risks bolt loosening and potential engine damage, while over-torquing can stretch or break the bolts themselves.

Always consult the vehicle’s service manual for the correct torque specification for each fastener. Employing the correct technique, alongside a properly calibrated tool, is non-negotiable when working with these essential engine components.

Wheel Lug Nuts: Ensuring Vehicle Safety

Wheel lug nuts are paramount to vehicle safety, and proper torque application is absolutely essential. These fasteners secure the wheels to the vehicle, and incorrect tightening can have severe consequences, including wheel detachment while driving. A torque wrench is not merely recommended, but a necessity for this task.

Always refer to the vehicle’s owner’s manual or a reliable service guide for the specified torque value for your vehicle’s lug nuts. Typically, this will be expressed in foot-pounds. Tighten lug nuts in a star pattern to ensure even pressure distribution.

Regularly check lug nut torque, especially after the first few miles following wheel removal or installation, as outlined in workshop accreditation guidance, to guarantee continued safety.

Troubleshooting Common Issues

Inaccurate readings or a wrench that won’t click indicate potential calibration needs; regular checks, like HBM’s transfer torque wrench recalibration, are vital.

Torque Wrench Not Clicking

A torque wrench failing to click when the set torque is reached is a common issue demanding immediate attention. Several factors can contribute to this problem, potentially compromising the accuracy and reliability of the tool. First, verify the torque setting is correctly adjusted and within the wrench’s operational range. Ensure the wrench is being used with a smooth, consistent pull – jerky motions can prevent the mechanism from engaging.

Internal lubrication can degrade over time, hindering the clicking mechanism; professional servicing might be required. A significantly worn or damaged wrench will consistently fail to click, necessitating replacement. Finally, remember that regular calibration, as highlighted by services utilizing GEDORE equipment, is crucial for maintaining proper functionality and preventing such issues. Ignoring a non-clicking wrench risks undertightening or overtightening fasteners.

Inaccurate Readings

Inaccurate torque wrench readings pose a significant risk, potentially leading to fastener failure or component damage. The primary cause is often a lack of regular calibration; tools drift out of specification with use. If readings seem consistently off, even after resetting, calibration is essential – services like those employing HBM transfer torque wrenches offer precise recalibration.

Ensure the wrench is used on a stable surface and with a perpendicular pull. Damage to the internal mechanism, potentially from dropping the tool, can also cause inaccuracies. Always inspect the wrench for physical damage before use. Remember, precision manufacturing relies on accurate tools, and a faulty torque wrench compromises product integrity and safety, as emphasized in workshop accreditation guidance.

Torque Wrench Standards & Accreditation

IRTE Workshop Accreditation highlights the necessity of regularly calibrated torque wrenches for vehicle safety, emphasizing precision and adherence to established standards.

IRTE Workshop Accreditation Guidance

IRTE Workshop Accreditation guidance clearly stipulates that torque wrenches are fundamental to maintaining vehicle safety and operational reliability. This accreditation demands rigorous adherence to calibration schedules and documented procedures for all torque-applying tools within a workshop environment.

Regular calibration isn’t merely a recommendation; it’s a core requirement for achieving and sustaining accreditation. Workshops must demonstrate a robust system for tracking calibration dates, managing tool maintenance, and ensuring technicians utilize correctly calibrated equipment. The guidance emphasizes that inaccurate torque application can lead to catastrophic failures, impacting both vehicle integrity and road safety.

Furthermore, the accreditation process assesses the workshop’s understanding of torque wrench limitations and proper usage techniques, reinforcing the importance of skilled personnel and consistent application of best practices. Maintaining detailed records of calibration and usage is paramount for demonstrating compliance and upholding the highest standards of vehicle maintenance.

Precision Manufacturing & Torque Wrench Importance

In precision manufacturing, the torque wrench transcends being a simple tool; it becomes a critical component ensuring product integrity and safety. These instruments bear the responsibility for maintaining exacting standards across countless applications, from aerospace assemblies to intricate automotive systems.

Consistent and accurate torque application directly impacts the reliability and longevity of manufactured goods. Deviations from specified torque values can induce stress, fatigue, and ultimately, component failure. Therefore, manufacturers rely heavily on calibrated torque wrenches and stringent quality control processes.

The demand for precision extends to the calibration of these tools, with services like HBM offering on-site recalibration for transfer torque wrenches, minimizing downtime and ensuring continuous accuracy. Investing in quality torque wrenches and adhering to proper calibration protocols is paramount for maintaining a competitive edge and delivering superior products.